PTFE V-rings are used mainly for sealing on plunger and piston rods of hydraulic cylinders, presses, valve spindles and controls. Several sealing lips and the long contact surfaces ensure a good sealing performance.

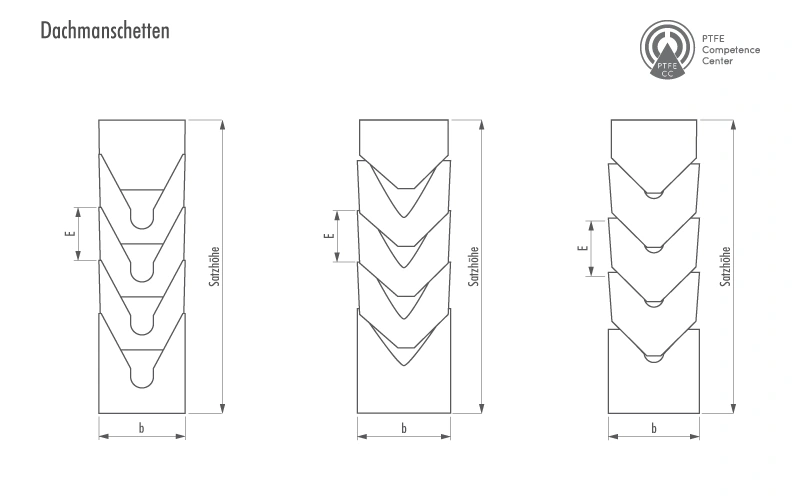

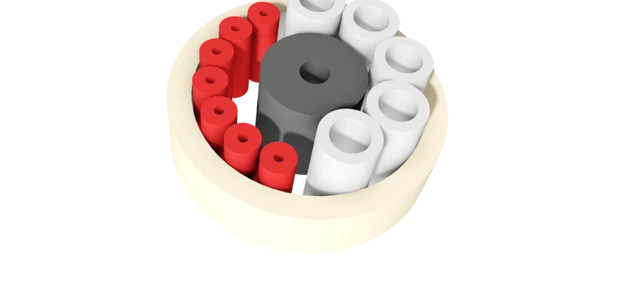

The seal sets consist of a pressure ring, a back-up ring and V-rings, which in number and design are adapted to the various operational conditions. This makes them more insensitive to contamination from the operating medium than one-piece seals. Further decisive advantages are their form stability, which make V-rings insensitive to pressure peaks, and their preload adjustability (spacer plates, springs). In addition, they have a favorable breakaway torque even after a long standstill period.

Standard profiles are manufactured from pure PTFE or PTFE with fillers. There is an elastic design for the low pressure range, a design is available for a broad product spectrum, where the sealing function is given due to a wedge effect and a pressure resistant, relatively rigid design for harsh operating conditions. V-seal sets are made by machining and can be produced in a variety of diameters and heights.